3pcs bedding set factories

A Comprehensive Guide to 3-Piece Bedding Set Factories

When it comes to furnishing a bedroom, quality bedding sets are essential for both comfort and aesthetics. Among the various options available in the market, 3-piece bedding sets have gained immense popularity due to their convenience and cohesive design. This article explores the intricacies of 3-piece bedding set factories, their significance in the home textile industry, and the factors that contribute to their success.

Understanding 3-Piece Bedding Sets

A typical 3-piece bedding set comprises a fitted sheet, a flat sheet, and a pillowcase. These sets are designed to provide a coordinated look for the bed while also ensuring comfort. They come in various materials, including cotton, microfiber, and linen, catering to different preferences and budgets. The popularity of these sets is a result of their simplistic nature; consumers appreciate the ease of shopping for matching items without having to piece together individual components.

The Role of Factories in Producing 3-Piece Bedding Sets

Bedding set factories play a crucial role in the production process, transforming raw materials into finished products ready for consumer use. These factories are equipped with advanced machinery and skilled labor to ensure that each piece meets quality and safety standards. The production process typically involves several stages, including fabric sourcing, cutting, sewing, quality control, and packaging.

Fabric Sourcing

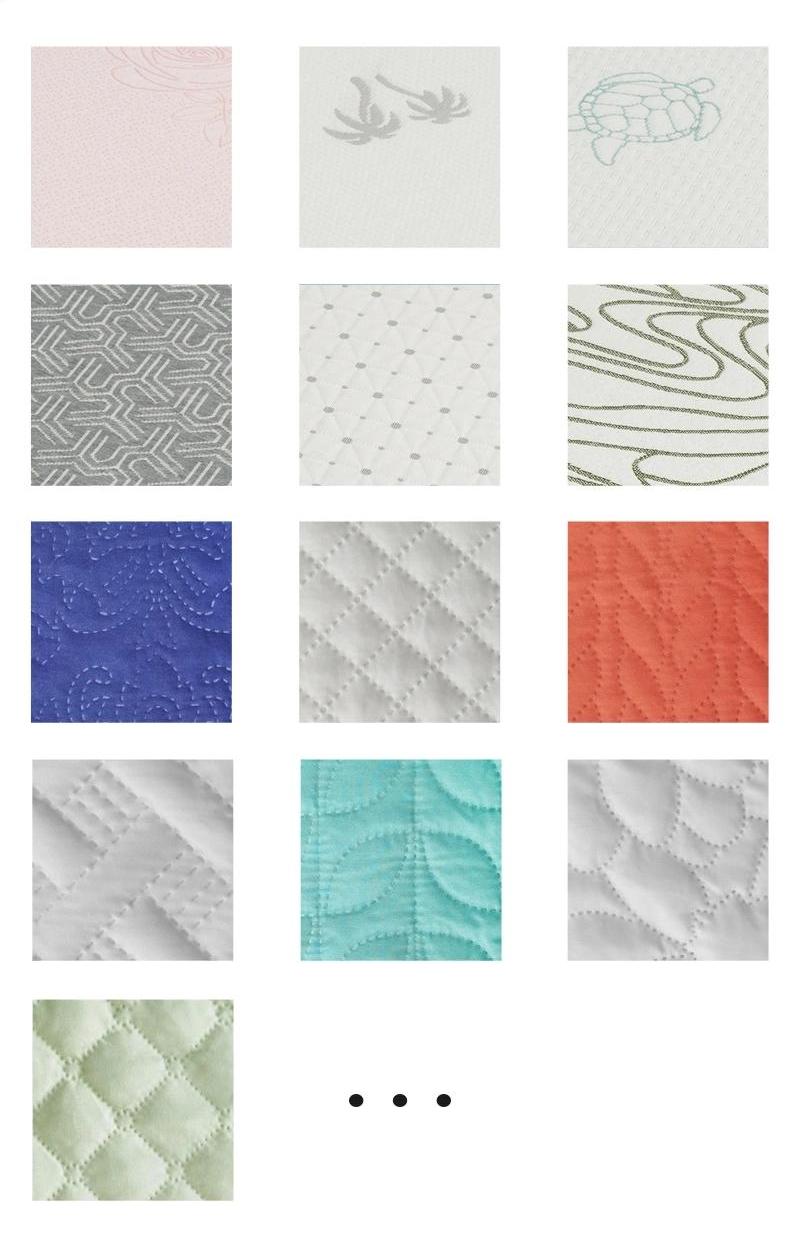

The first step in manufacturing bedding sets is sourcing high-quality fabrics. Factories often have relationships with suppliers from different regions to ensure a diverse selection of materials. Cotton remains the most popular choice due to its softness and breathability, while synthetic fibers like polyester are also commonly used for their durability and affordability.

Cutting and Sewing

After the fabric is sourced, it undergoes a cutting process where patterns are created based on the dimensions of the sheets and pillowcases. Once cut, skilled workers sew the pieces together. Factories invest in both manual and automated sewing techniques to enhance efficiency while ensuring a high level of craftsmanship.

3pcs bedding set factories

Quality Control

Quality control is a critical aspect of bedding set manufacturing. Factories implement stringent inspection processes to check for defects, such as uneven stitching or fabric flaws, before the products are packaged. This step not only ensures that consumers receive top-notch products but also helps maintain the factory's reputation in a highly competitive market.

The Importance of Sustainable Practices

In recent years, there has been a growing emphasis on sustainability within the textile industry. Many 3-piece bedding set factories are adopting eco-friendly practices, such as using organic cotton and reducing water consumption during the production process. These efforts not only appeal to environmentally conscious consumers but also contribute to the factory's long-term viability in a changing market landscape.

Challenges Faced by Bedding Set Factories

Despite the growth of the bedding industry, factories encounter several challenges. Fluctuating raw material prices can impact production costs, while global supply chain disruptions affect timely delivery. Additionally, competition from low-cost manufacturers, particularly in developing regions, puts pressure on factories to innovate and maintain competitive pricing without compromising quality.

The Future of 3-Piece Bedding Set Factories

Looking ahead, the future of 3-piece bedding set factories appears promising. As consumer preferences shift towards personalization and sustainability, factories that can offer customizable options and eco-friendly products will likely thrive. The integration of technology, such as artificial intelligence and automation, will also enhance production capabilities, allowing factories to respond quickly to market demands.

Conclusion

In conclusion, 3-piece bedding set factories play a pivotal role in the home textile industry, providing consumers with comfortable and aesthetically pleasing products. By prioritizing quality, sustainability, and innovation, these factories can navigate the challenges of the modern market and continue to meet the evolving needs of consumers. As the demand for high-quality bedding remains strong, these factories are poised for growth, ultimately contributing to better sleep and enhanced bedroom decor for households worldwide. With the right strategies, they can not only survive but thrive in an increasingly competitive landscape.

-

Hotel Textiles: The Backbone of Luxurious HospitalityNewsJul.15,2025

-

Exploring the World of Home Fashion TextilesNewsJul.15,2025

-

Bedding Textiles: The Perfect Blend of Comfort and StyleNewsJul.15,2025

-

Baby Accessories for Newborns: Essential Items for Your Little OneNewsJul.15,2025

-

Airplane Comfort Accessories: Enhance Your Travel ExperienceNewsJul.15,2025

-

Air Travel Blanket: The Ultimate Comfort for Your JourneyNewsJul.15,2025

- Product Categories

- • Hospital Used Fire Retardant Bedding

- • Hotel Textiles

- • Airline Textiles

- • Hometextiles

- • Infant Cloth

- Quick Links

- • Home

- • Products

- • About us

- • News

- • Contact

- Contact Us

-

Tel: +8631187701449

-

Fax: +86 311 8770 1444

-

E-mail: sale@hometex-suntex.com